Why controlling sound is so important

Acoustic absorption plays a vital role in shaping how we hear and experience sound in any space—whether it's a recording studio, restaurant, office, or home. Without treatment, sound waves bounce off hard surfaces, creating long and unpleasant reverberation times. This can blur detail, mask the original sound source, and make communication or listening uncomfortable. Read More

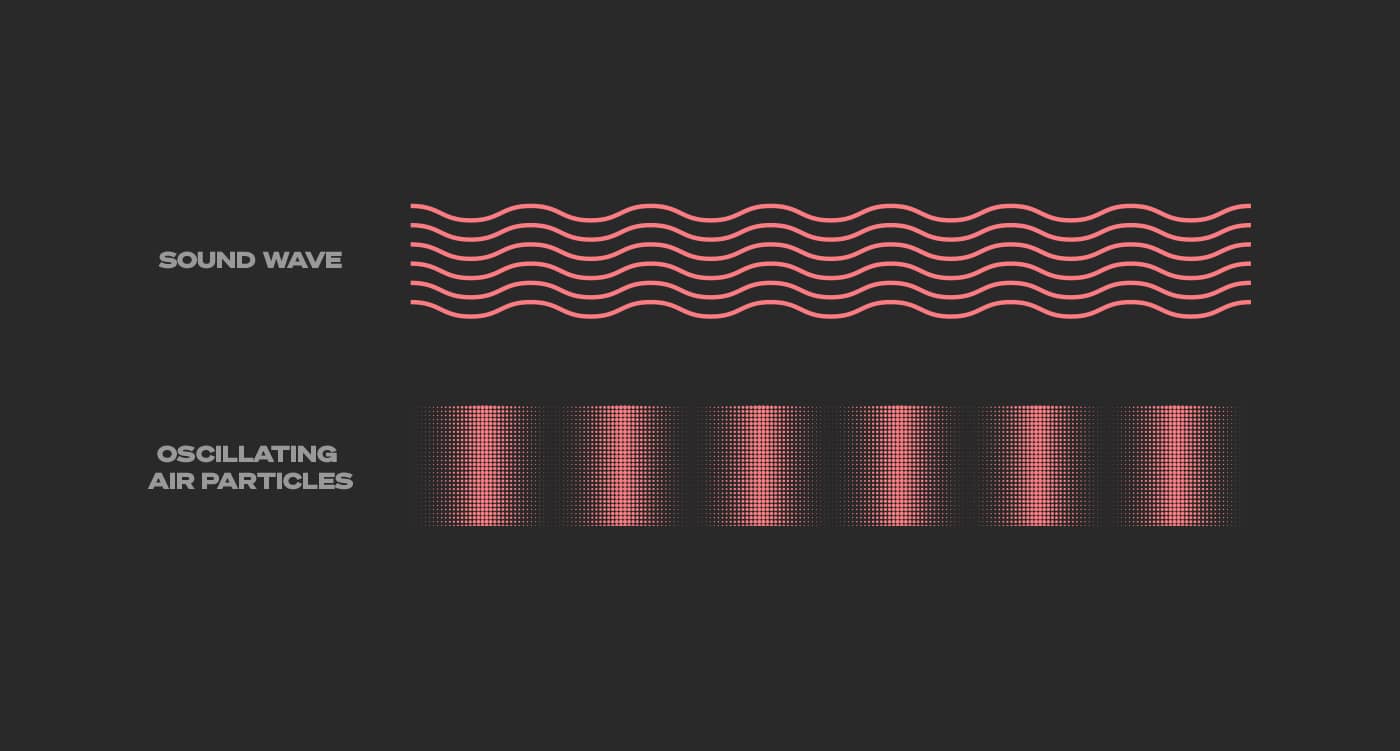

How sound absorption actually works

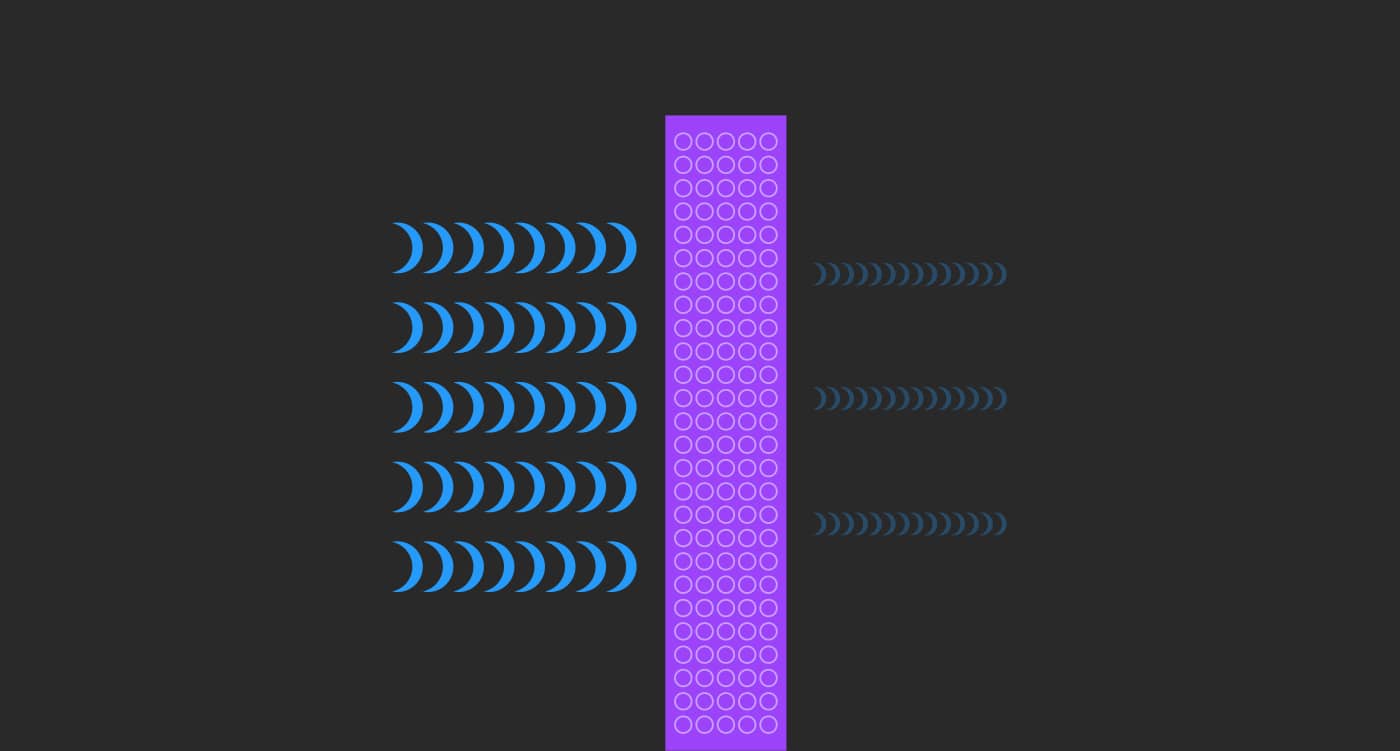

To absorb sound efficiently without taking up unnecessary space, a material must be porous—packed with tiny air pockets. As a sound wave travels through this labyrinth of fibres or cells, it repeatedly transitions from air to solid and back again. Each transition creates friction, converting a small portion of the wave’s energy into heat (imperceptibly low). This gradual loss of energy is called dissipation. Read More

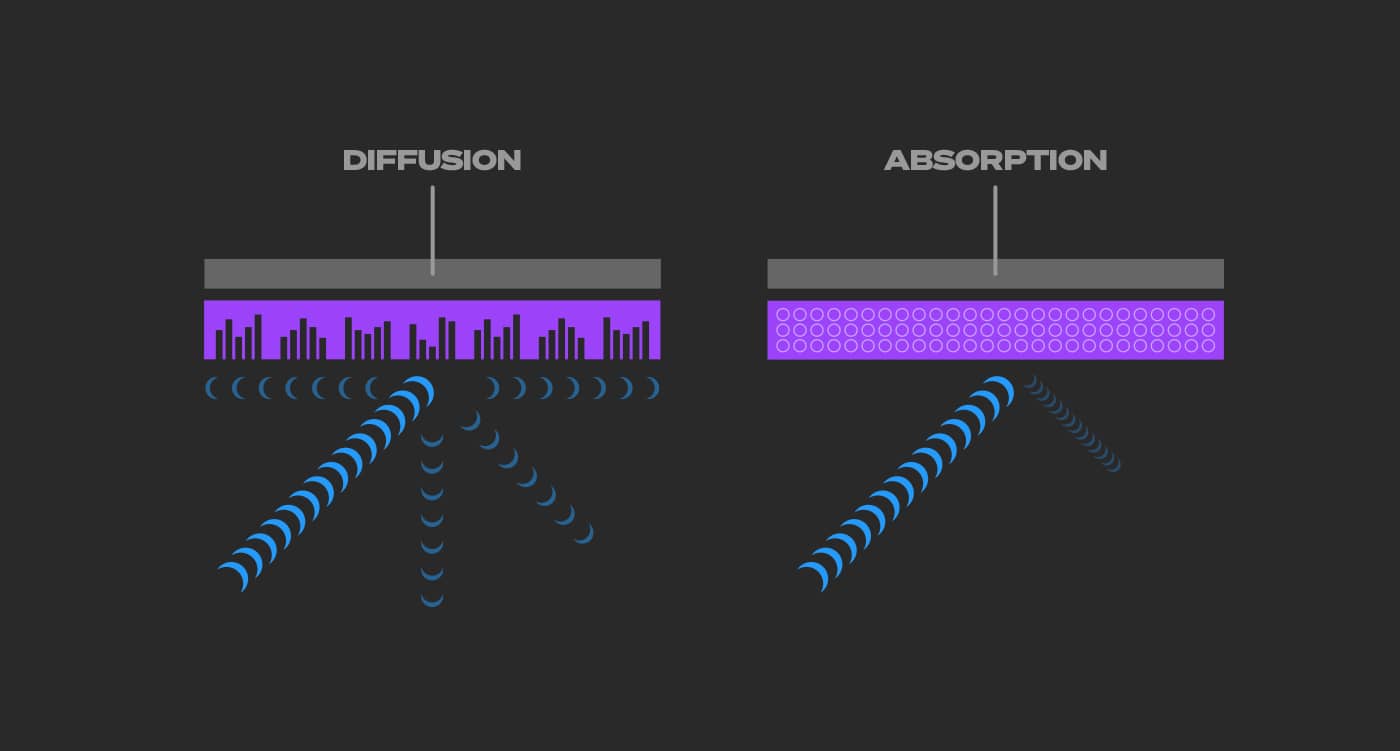

Diffusion and absorption

While diffusion and absorption are technically opposites, they are often used together to achieve balanced acoustics. Absorption works by removing sound energy from a space, helping to create a quieter, more controlled environment. Diffusion, on the other hand, is designed to scatter sound energy rather than eliminate it—preserving a room’s liveliness while avoiding harsh echoes or focused reflections. Read More

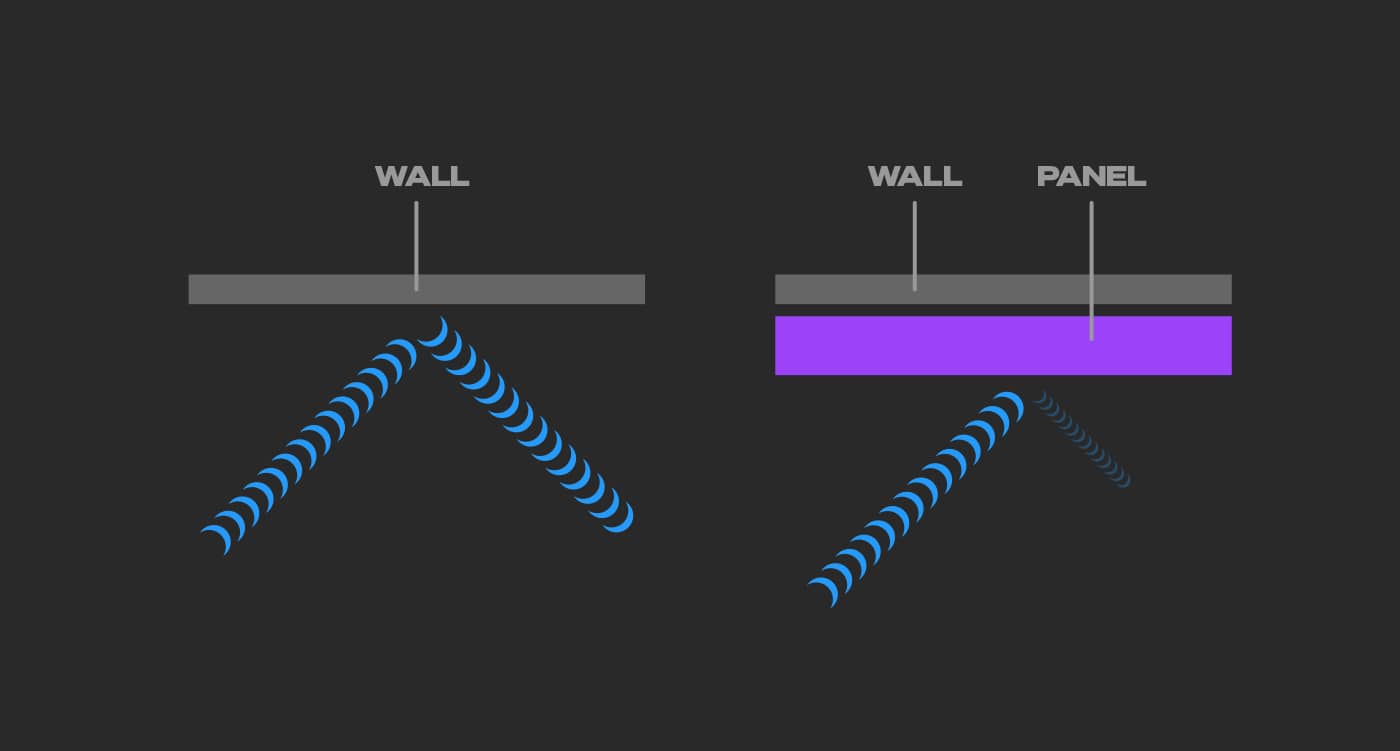

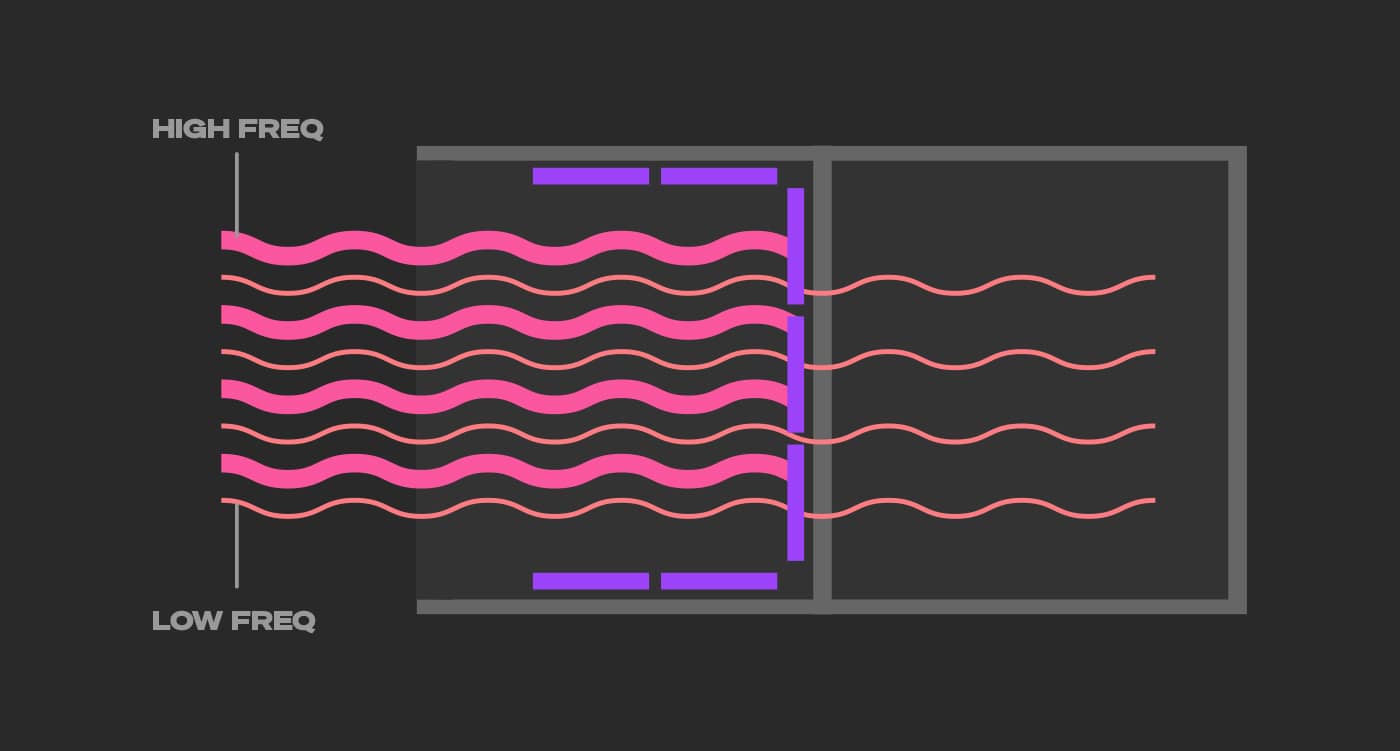

Treatment Vs Proofing

Sound treatment and soundproofing are often confused, but they serve very different purposes. Treatment focuses on improving the acoustic quality within a room—reducing echo and creating a more controlled listening environment. Soundproofing, on the other hand, is all about preventing sound from entering or leaving a space. It deals with sound isolation, not sound control. Read More

Densities, gas flow and material types

There’s often confusion around the role of density in sound absorption, especially when comparing different insulation materials. Many people assume that higher density automatically means better acoustic performance—but in reality, the more relevant factor is usually gas flow resistivity. Read More

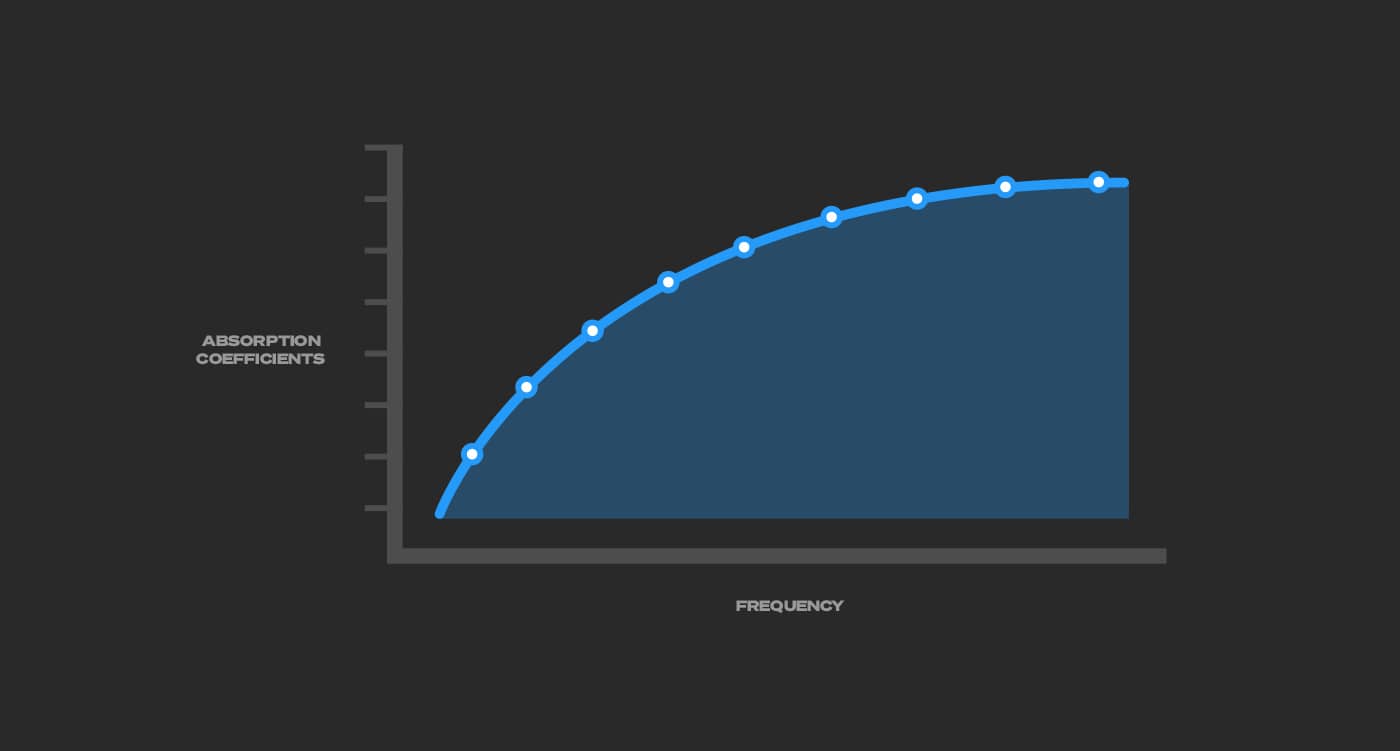

Absorption coefficients, Noise Reduction Coefficients (NRC) and R-values

Absorption coefficients, Noise Reduction Coefficients (NRC), and R-values are common ratings you’ll see when comparing sound-absorbing materials, each describing different aspects of their performance. Read More

Polyester vs other insulation absorbers

We use polyester insulation in all of our products for several key reasons. One of the most important is its safety — polyester is 100% allergy free, containing no breathable fibres and posing no health risks. This makes it a much safer choice for indoor environments compared to some other insulation materials, which may shed fibres or require protective handling. Read More

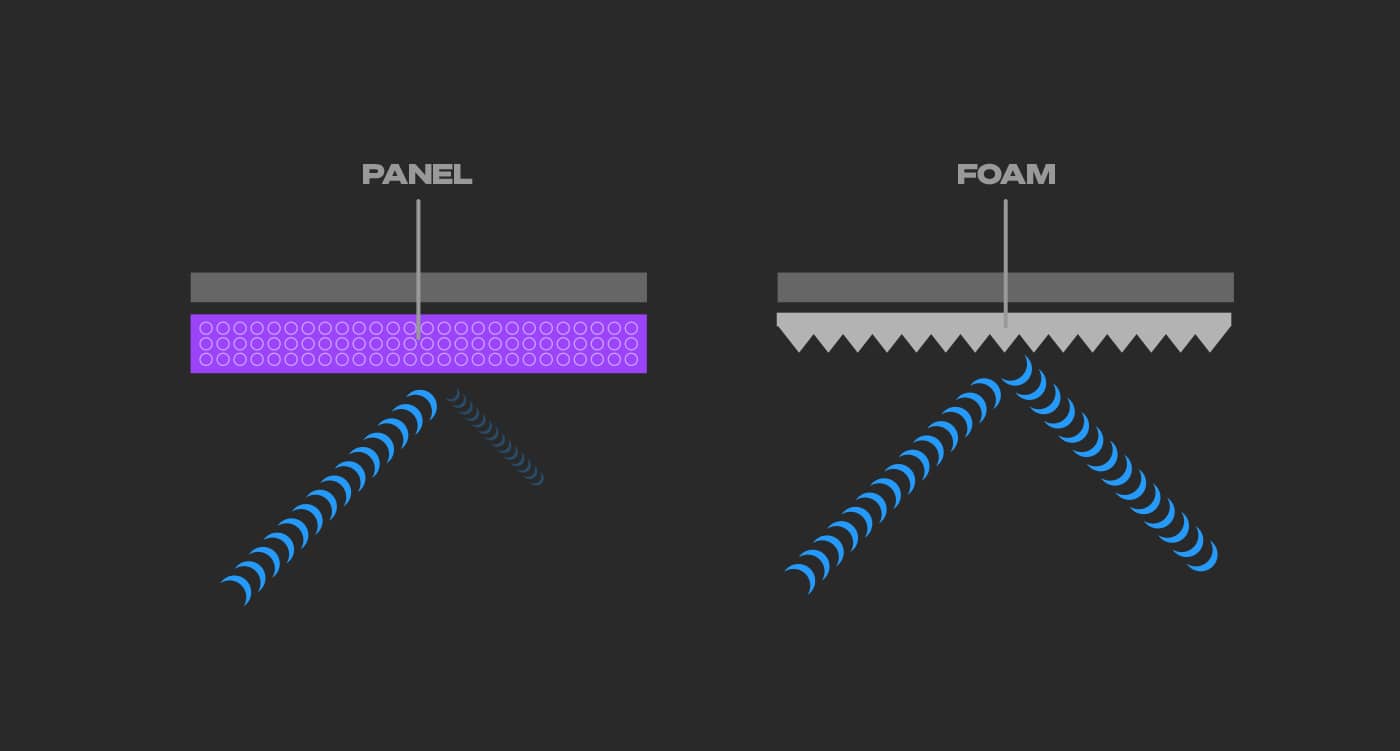

The Foam Fallacy

Foam is one of the most widely used materials for treating rooms, primarily because it’s cheap to manufacture, lightweight, and easy to ship. This has made it a go-to product for large-scale companies looking to market a quick-fix solution. Unfortunately, its popularity is more about convenience and cost than acoustic performance. Read More